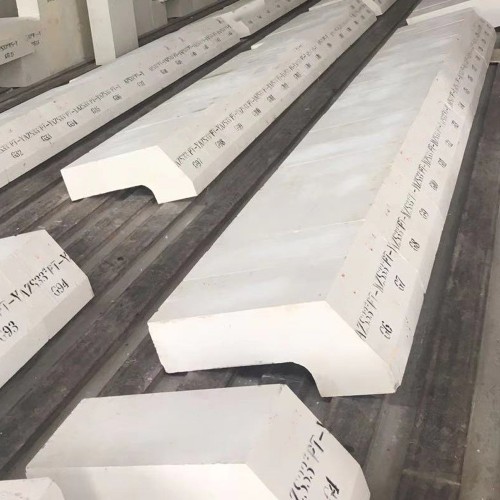

Fused Cast AZS33#

Products of Oxidized Fused Cast AZS Blocks Oxidized fused cast AZS blocks are formulated with high purityraw material and manufactured by long electric arc oxidizedfused cast process. This process combined with superior high purity raw material contributes to high corrosion resistance of oxidized fused cast AZS blocks to melting glass,and minimal contamination to molten glass.

AZS-33# is the Alumina-Zirconia-Silica fused cast material with> 32%ZrOz made by oxidizing process.lts microstructure makes a feature of zirconia,corundum and eutectoid crystals assembly,certain amount of the glassy matrix,resulting in unique properties. The good cast-ability of this material enables the products of many complex and varied shapes.

It is suitable for super-structure of Melter, Sidewall of Working End, Paving of Working End and Fore-hearth,etc.

| Physical and chemical index of Fused Cast AZS | ||||

| Properties | Products | |||

| AZS-33 (AZS-1681) |

AZS-36 (AZS-1691) |

AZS-41 (AZS-1711) |

||

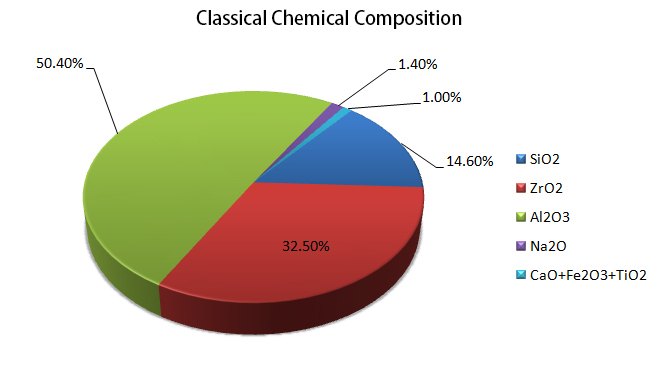

| Chemical Composition(%) | Al2O3 | 50.00 | 49.00 | 45.00 |

| ZrO2 | 32.50 | 35.50 | 40.50 | |

| SiO2 | 15.50 | 13.50 | 13.00 | |

| Na2O+K2O | 1.30 | 1.35 | 1.30 | |

| Physical Properties | Volum density(g/cm3) | 3.75 | 3.85 | 4.00 |

| Apparent porosity(%) | 1.2 | 1.1 | 1.0 | |

| Cold crushing strength(MPa) | 300 | 300 | 300 | |

| Refratoriness under load (T0.6,℃) | 1700 | 1700 | 1700 | |

| (1300℃×10h) Bubble index (%) | 2.0 | 2.0 | 2.0 | |

| (500℃ X36h) Corrosion Resistamce to glass melt (mm/d) | 1.5 | 1.4 | 1.2 | |

| Apparent Density(g/cm3) | PT | 3.45 | ||

| ZWS | 3.65 | 3.75 | 3.85 | |

| WS | 3.70 | ≥3.80 | ≥3.90 | |

| Crystallographic Analysis(%) | Zirconia | 34 | 36 | 41 |

| α-Alummina | 49 | 47 | 45 | |

| Glass Phase | 17 | 17 | 14 | |